Disconnect switches are a vital component of any electrical system, providing a safe way to isolate equipment for maintenance or in emergencies. These devices interrupt the flow of current, protecting workers and equipment.

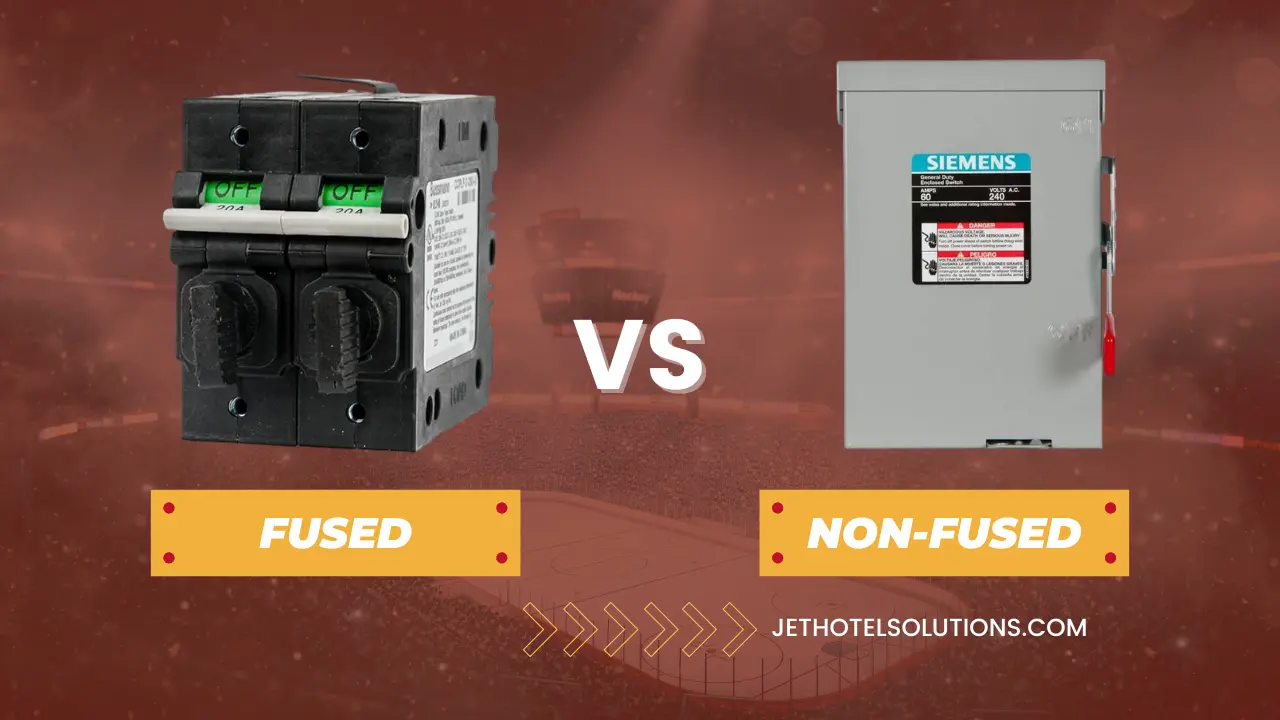

There are two main types available: fused and non-fused. Choosing the right disconnect switch for your application requires understanding key differences between these models.

For hotels and other hospitality businesses, having the proper disconnect switch is crucial for keeping guests comfortable and property safe.

What is a Disconnect Switch?

Disconnect switches are governed by electrical codes and standards that dictate their design, construction, and use. They provide a way to safely disconnect power and lock it out for service. They differ from circuit breakers, which automatically interrupt overloads but can be easily reset, allowing current to resume flowing.

For hotels, being able to safely isolate equipment like HVAC units or pools is essential maintenance. Disconnect switches located properly allow staff to de-energize circuits correctly when needed.

Fused vs. Non-Fused: What’s the Difference?

- Non-fused disconnect switches simply open or close the contacts to break the circuit. They offer no overcurrent protection on their own.

- Fused disconnect switches integrate fuses that blow and open the circuit if amperage rises above safe levels, providing overcurrent protection.

Fuses are a proven, reliable technology made of a thin conductor that melts and separates if specified current limits are exceeded. This disconnects the electricity rapidly. For hotels, this fast reaction prevents damage to valuable systems like elevators or commercial laundry equipment.

Non-fused switches rely solely on the contacts to interrupt current. The circuit breaker or upstream fuses handle any overprotection needs. This approach can work well for lighting systems in guest rooms, for example.

Applications for Fused Disconnect Switches

Fused disconnect switches offer valuable overcurrent protection in addition to isolating circuits, making them well suited for:

- Large commercial equipment – Kitchen appliances, elevators, and HVAC systems common in hospitality settings can benefit from the quick-blowing fuse protection.

- Hazardous locations – Commercial kitchens require extra safety steps like fused disconnects.

- High voltage applications – Hotel equipment running over 600V needs the fast reaction of fuses to prevent damage from surges.

- Multiple disconnect needs – Fusible switches can be designed to disconnect several circuits at once, important in complex hotel systems.

- When protection is far away – Fuses integrated right at the equipment provide faster protection if the main overloads are located in a distant panel.

Non-fused disconnect switches work well in lower power guest room lighting circuits. They’re also very common in motor control centers where each starter gets its own disconnect.

The Benefits of Fused Disconnect Switches

Fused disconnect switches provide valuable benefits:

- Quick reaction – Fuses blow in milliseconds if an overload occurs, preventing system damage.

- Added safety – Fuses stop current cold without relying on electronics that could fail. They reduce arc flash risks to maintenance staff.

- Easy visual verification – Blown fuses clearly indicate an overload occurred, and which circuit. Facility managers can quickly identify issues.

- Lower maintenance – Fuses are sacrificial components designed to fail; the switch itself sees less stress and wear over time.

- Higher short circuit ratings – Fuses increase the disconnect’s interrupting capacity.

- Smaller size – The required ampacity of the switch itself can be lower since fuses provide overcurrent protection. This allows fitting more disconnects in tight electrical rooms.

However, there are some downsides. Fused disconnect switches are more complex with more components. They are larger and cost more than non-fused equivalents with the same ratings. And blown fuses aren’t simply reset – they must be replaced.

Choosing Fuses for Protection

If opting for a fused disconnect switch for a hotel or kitchen equipment, the proper fuses must be selected. Standard fuses are designed for systems up to 600V. Two common fuse types are:

- Fast-acting – These respond very quickly to overloads but allow temporary inrush currents when equipment starts. Recommended for motors.

- Time-delay – These allow temporary overloads but will blow if excessive current continues over time. Good for handling start-up surges.

High voltage systems require special fuses with designated ratings. Coordinate fuse amp rating with equipment loads, and choose the fuse class, voltage rating and speed appropriately.

Properly sized fuses maximize protection. Underrated fuses blow too easily and cause nuisance trips. Overrated fuses won’t blow fast enough to prevent damage. Consult disconnect switch manufacturers to select the ideal fuse type and amperage.

The Role of Non-Fused Disconnect Switches

In lower voltage circuits where surges are less likely, non-fused disconnect switches can provide reliable power control. Benefits include:

- Lower cost and smaller size – Without fuses, non-fused switches use a simpler and more compact design. This can help reduce installation costs.

- Avoid nuisance tripping – Non-fused types won’t trip from short temporary overloads that fuses would react to unnecessarily. This prevents disruptions to guests.

- Less maintenance – There are no fuses to replace after use. The switch itself is very durable across many cycles.

- Faster resetting – Power can be restored instantly after an overload simply by flipping the switch back on quickly.

These switches rely on upstream breakers or fuses for overload protection since they have no built-in protection. This makes sizing those components correctly critical for safety.

Non-fused disconnect applications include HVAC equipment, pumps, machine tools, and any environment where temporary current spikes are acceptable and won’t harm systems. They provide reliable on/off capability without nuisance tripping. Lighting circuits are ideal for non-fused disconnects.

Best Practices for Disconnect Switch Safety

To fully benefit from these essential devices, proper selection, installation, and use is crucial:

- Choose an appropriate switch for the voltage, load current, and environment. Consider fused or non-fused models based on the circuit’s needs.

- Mount the disconnect switch near the equipment it serves. It should be readily accessible to facilities staff.

- Use short, oversized wiring between the disconnect and equipment to minimize voltage drops when reenergizing motors.

- Label disconnect switches clearly to identify which equipment they control. Color coding helps too.

- Always follow proper lockout/tagout procedures when accessing equipment connected to disconnects. Train staff on this.

- Specify weatherproof enclosures for outdoor disconnect switches to prevent corrosion, debris, and moisture damage.

- Include a grounding lug to attach equipment ground wires for safety. Ensure the ground is bonded to the disconnect enclosure as well.

With robust construction, accurate sizing, and smart placement, disconnect switches reliably deliver safety and flexible power control for hospitality applications.

For new hotel construction or renovations, the team at JET Hotel Solutions (https://www.jethotelsolutions.com/) partners with properties to specify the right disconnect switches during design. For existing buildings, we offer disconnect switch upgrades and replacements to keep systems running safely.

With decades of experience serving the lodging industry, We provide deep expertise in engineering design, installations, and maintenance.